Flow path optimization

In response to the low flow efficiency of domestic blast furnace gas residual pressure turbines, advanced turbine optimization technology from Germany is introduced to provide a complete set of TRT flow efficiency improvement solutions, solving the pain points of users in actual TRT operation.

Analysis of the reasons for low flow efficiency of domestic TRT units

The aerodynamic design of vanes and blades is relatively backward, and there are many problems in the distribution of airflow

Advanced turbine efficiency raising optimization techniques

Check TRT rotor dynamics design and strength design, blade stress analysis; Blade frequency and vibration analysis; Blade root section stress analysis. Keep the original static blades adjustable, optimize the regulation characteristics, and better participate in the top pressure stabilizing control.

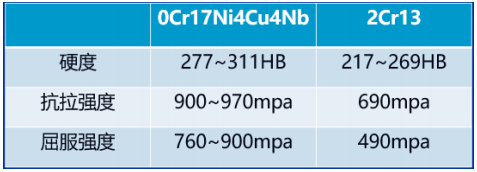

For TRT units with high dust content and short life due to severe blade corrosion, material upgrade and special ceramic coating process measures are adopted. Blade material upgrade, all moving and stationary blades upgraded to 17-4PH (0Cr17Ni4Cu4NB).

0Cr17Ni4Cu4NB is a precipitation hardened Martensitic stainless steel composed of copper, niobium/columbium, with high strength, hardness and good corrosion resistance. After heat treatment, the mechanical properties of the product are more perfect, with tensile strength up to 890~1030 N/mm ², good corrosion resistance to acids or salts, and better performance than 2Cr13.

For some TRT models with broken blades, the problem of broken blades is effectively solved by blade redesign and material upgrades.

It is able to analyze the energy efficiency index of gas turbine on line and in real time, while producing a large amount of data for the operation. Through the system intelligent algorithm and the expert system, the operation optimization suggestions are given to make the unit operate in a higher efficiency point region. For blade dust accumulation and blade erosion corrosion, the degree of blade dust accumulation and blade erosion are given by artificial intelligence through an embedded intelligent prediction module, which provides a scientific basis for taking corresponding measures.